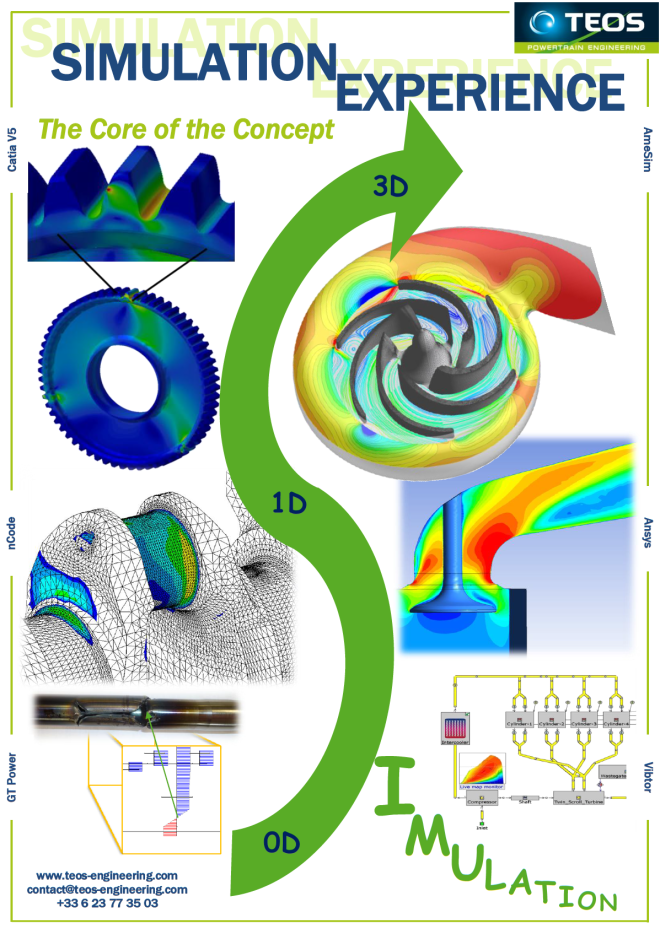

SIMULATION Experience

TEOS POWERTRAIN ENGINEERING relies on a series of well-proven tools and methodologies to fully design and compute the engine parts virtually.

The know-how covers:

- Mechanical design: complex fully machined parts, casings, moving parts, gears, fatigue

- Thermal & fluid calculations : internal cooling, lubrication, air permeability

- Global performance prediction

- Integration of turbochargers, electric machines, cooling systems, etc.

The main engineering tools are:

- CAO: CATIA V5

- FEA: GPS-GAS, ANSYS MECHANICAL

- CFD: ANSYS CFX

- Performance and Energy balance modelization: GT POWER / in house tools

- Dynamic torsion/flexion: AMESIM / RBSDYN / in house tools

- Shell and ball bearing: ACCEL / CAROL / RBSDYN / in house tools

- Gears: TEOS POWERTRAIN ENGINEERING tools

The company also uses the engineering tools of its mother company, IFP Energies Nouvelles, such as:

- 3D combustion calculation and combustion chamber design

- Combustion analysis

- Embedded energy management